Technical

| Subject | Images |

|---|---|

The route to a more eco friendly packaging is to switch from plastic materials over to paper materials. Is this really the case? Paper is a more recyclable material on its own. However, it is another story when paper is coated with plastic. If the recycling ecosystem for plastic coated paper is not set up in the neighborhood, plastic coated paper may be harder to recycle than plastic alone. Furthermore, the process of producing paper is more water intensive than plastics. Using paper also means taking the risk of over deforestation if paper is not sourced sustainably. So, is paper really more eco-friendly than plastic? In this article we will look at the bigger picture to explore the pros and cons for both paper packaging and plastic packaging.

If you are on a water-based printing operation or thinking about switching to a water-based printing operation, then you must understand the common water-based printing issues which include 1. Ink foaming 2. gelation 3. light ink color 4. and poor drying.

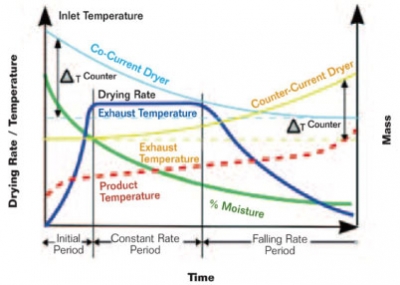

Rotary dryers can come in two types of airflow configurations. The co-current system and the counter current system. Co-current system is designed so that the airflow and material flow in the same direction. On the other hand, counter current system is designed so that the airflow and the material flow in the opposite direction. To decide which system to adopt will depend on the type of substrate, ink and coating solution used. In this article we will lay out the advantages and disadvantages of both systems for you to review.