Technical

| Subject | Images |

|---|---|

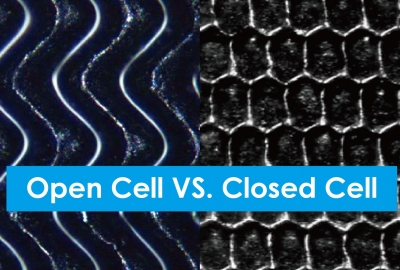

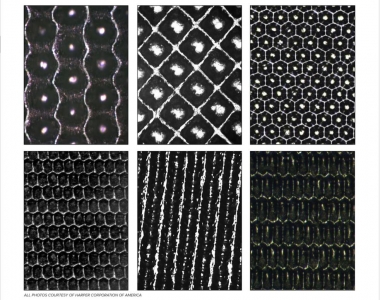

When choosing an anilox, should I go for an open cell or a closed cell system? The answer to the question depends on what you are working with (ink type, ink viscosity, plate LPI) and what you would like to achieve (printing, coating, half-tone, solid). In this article we will be looking into the characteristics of an open cell system and a closed cell system. To address issues such as ink spitting and pinholes and how to solve them from a cell system’s perspective. Furthermore, going into a few scenarios including high speed printing, UV ink application, special ink / coating enhancement, where certain cell designs may be recommended over the others.

What does wide tension range Flexographic press imply? The different substrate will require different tension range during the printing process. Therefore, the wider the tension range of a Flexographic press means that the more materials the press can take on. On a KYMC press, a tension range of 25N to 350N is achievable. At this tension rage, many different materials can be printed. For instance, PP, BOPP, LDPE, CPP, HDPE, PET, paper…etc.

Reprint capability can make your life easier in today’s business environment. Let’s discuss why is that? Undeniable, Flexography practitioners will agree that production variations and uncertainty levels are much higher today than before. These are caused by the brand’s need to attract and fulfill the consumers' ever-changing appetites. Therefore, variations and uncertainties are here to stay. The only thing that you can do is to adapt. There are many ways to adapt. In this article, we will discuss how your Flexographic press can help you adapt through its reprint capability.

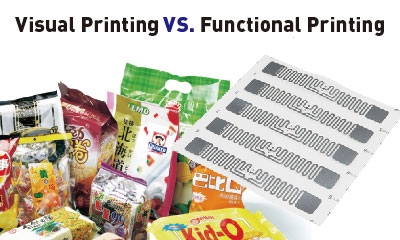

Visual printing refers to the presentation of the print. How well does the print come out visually in front of the audience? Does it serve its marketing purpose of appealing to the audience? On the other hand, functional printing is about the properties and functionalities delivered through the print. How well does it perform to carry out the actions that it is intended to? In this article, we will explore the differences between visual printing and functional printing from their applications and quality assessment methods. At the same time to discuss the scenarios and potential of combining visual printing and functional printing together.

Gearless Servo Flexographic press has become increasingly popular among the printing and packaging industry. A Servo Flexographic press is able to maintain print quality, reduce startup time and waste better. Many know that gearless servo presses are more precise when it comes to color registration and impression control when compared to a geared press. But why is it more precise? When is it more precise? Are there any other advantages besides being more precise? In this article we will compare the difference between a gearless servo press with a geared press.