Technical

| Subject | Images |

|---|---|

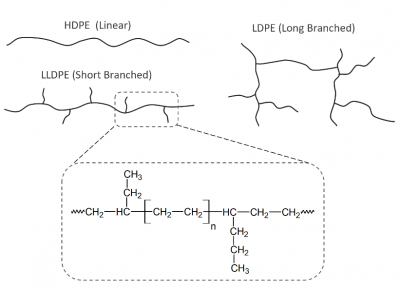

The flexo or flexographic printing press is used commonly in the food packaging industry. The flexo or flexographic press is commonly associated with the plastic industry as many of the food packaging products use plastics. Besides the food packaging industry, the flexo printing press is also associated with industries including paper bags, carton and cardboard boxes, medical packaging, sanitary product labels, and the diaper industry. In recent years the flexo printing press is also found in the process for printed electronics manufacturing such as RFID, OLED lighting, functional substrates, circuit boards, and sensors.

To help us make a decision of using a motor or brake for the tension control, we can first understand the pros and cons of each from 6 perspectives. Tension Precision, Cost, Maintenance, Installation, Torque Requirements and Energy Consumption.

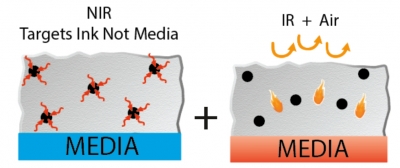

A test study was conducted by adphos, an NIR drying solution provider. To replace an IR + hot air drying with aNIR® (advanced Near InfraRed) resulted in an 60% in print speed from 500fpm to 800fpm for high coverage sample job.

Communication has enabled society to advance. To be able to commutate effectively and efficiently has separated humans from all other species on the planet. People commutate in text, in sound, in code, in pictures…etc. People commute in many different languages, English, Chinese, Spanish, Malaysian…etc., you name it. As a printing professional, how do we communicate in color? What is the common color language that enables us to be on the same page?

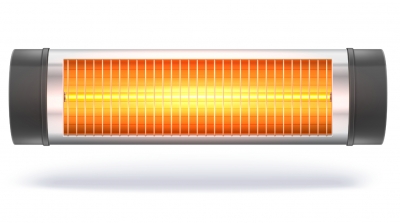

Drying process applies or generates heat to evaporate the water or solvents in the ink, leaving the pigment behind on the substrate to provide color. The curing process is the process to solidify the ink from liquid to solid...

Drying is one of the most important factors in printing. You can print with great registration. You can print with great speed. At the end of the day, if the ink doesn’t dry, your end result wouldn’t come out good. There are many drying methodologies. In this article, we are going to explore one of the drying technologies, Infrared.

As the society lean towards more environmentally friendly production solutions. The plate making industry searches for a greener plate making process. Let’s compare some of the plate making processes.