The IR Drying Unit

Drying is one of the most important factors in printing. You can print with great registration. You can print with great speed. At the end of the day, if the ink doesn’t dry, your end result wouldn’t come out good. There are many drying methodologies. In this article, we are going to explore one of the drying technologies, Infrared.

IR drying stands for infrared drying. Heat or thermal energy is a commonly used drying process. Traditionally, heat is introduced through the blowing of hot air onto the substrate. When the heat is applied, the water and solvents in the ink will evaporate, leaving the pigment behind on the substrate to provide color. The way IR drying introduces heat is through the emission of infrared radiation. The heat energy is directly transferred from the infrared source to the product to be heated without the need for an intermediate such as air or water. It is important to select the infrared emitters with the suitable spectra according to the product to have an optimized absorption of the radiation that will be subsequently converted into heat.

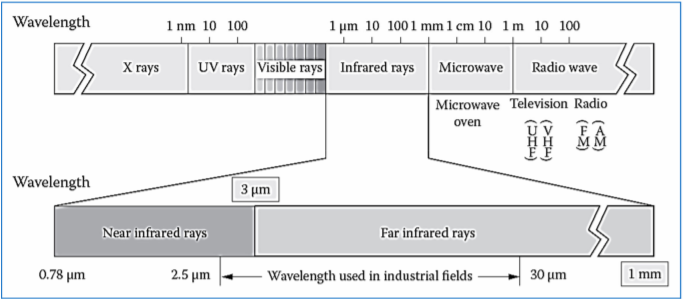

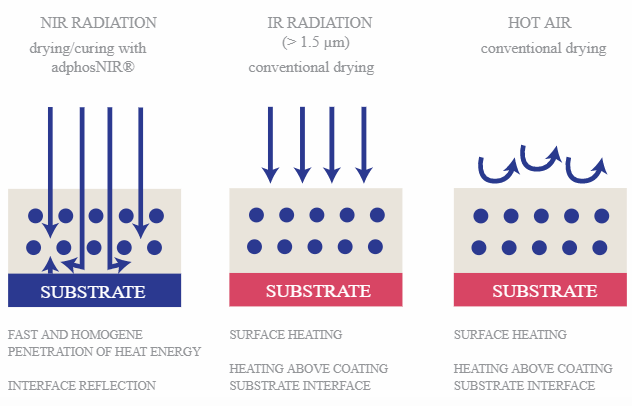

The infrared radiation wavelength is usually between 0.75 µm to 1,000 µm. The wavelength could be separated into 3 main categories: Near-IR(NIR), Mid-IR(MIR), and Far-IR(FIR). Near-IR (NIR) whose wavelength ranges from 0.75 to 1.4 µm at temperatures below 400 ◦C, and mid-IR (MIR) whose wavelength is between 1.4 and 3 µm at temperatures between 400 and 1000 ◦C and far-IR radiation (FIR) wavelength of 3–1000 µm at temperatures above 1000 ◦C. Infrared penetration causes vibrating movement of water molecules at a frequency of 60,000–150,000 MHz and thereby causes heating. In general, NIR provides a more efficient process as the short wavelength allows it to penetrate through the ink and provide a faster and homogeneous drying process. As Illustrated below (provided by Adphos technology )

The advantage of and IR drying system compared to a hot air-drying system includes

- IR drying can transfer energy without contact

- Infrared radiation could be adjusted precisely to where it is needed

- IR with optimal wavelength can accelerate drying

- Shorter drying path

- IR drying has a higher overall efficiency

Relevant Reading

Drying V.S Curing

Article by Daywey Chen, KYMC

Source: Review A Comprehensive Review on Infrared Heating Applications in Food Processing, MDPI