NIR drying system increase printing speed by 60%

A test study was conducted by adphos, a NIR drying solution provider. To replace an IR + hot air drying with aNIR® (advanced Near InfraRed) resulted in a 60% increase in print speed from 500fpm to 800fpm for high coverage sample job.

The test was conducted on a HP T4xx inkjet press. A high print coverage job was performed on paper on two similar presses, press number 1 equipped with three IR + hot air drying module. Press number 2 is equipped with one aNIR drying module and two IR + hot air drying module.

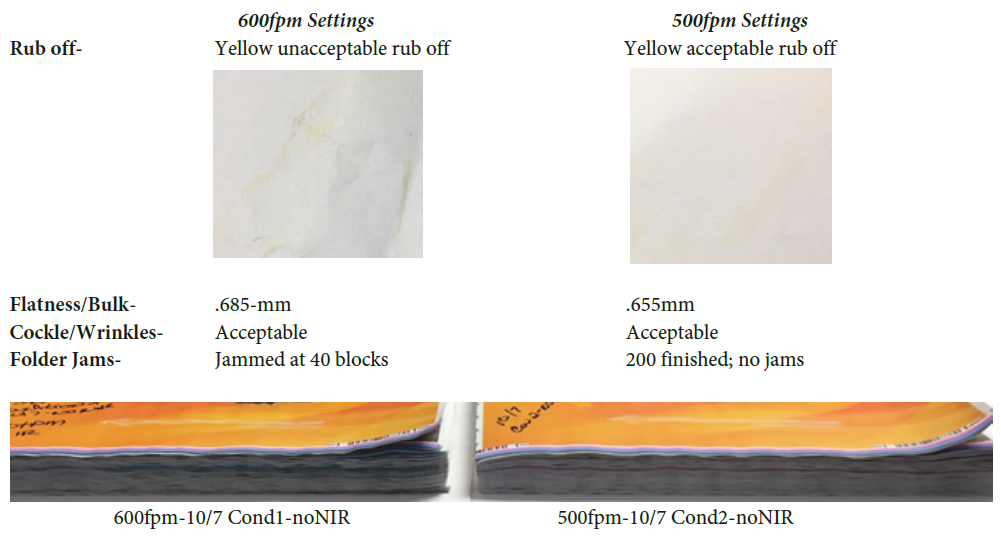

High Coverage Print Result

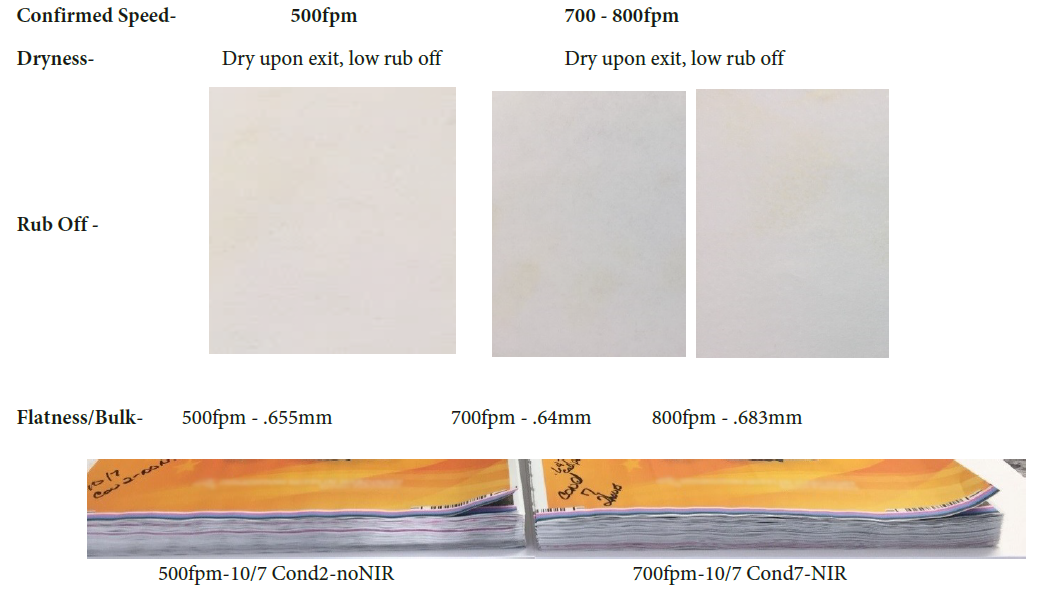

On Press 1, printing high coverage file at 600fpm creates a wetter sheet upon exit with more yellow ink rub-off, thicker book block (bulk) from paper cockle and causing quicker finishing jams. With aNIR at 700 and 800fpm, yellow transfer was considerably reduced, and ink was much drier upon exit for stacking, reducing rub off from weighted stacks.

Press 1 (without aNIR)

Press 2 (with NIR)

During IR + hot air drying methods we need to consider the effect of heat that has on the substrate, introducing too much heat will cause paper substrates to wrinkle. However, introducing too little heat will prevent the ink from drying completely. Therefore, constraining the printing press to run at a higher speed. The implementation of the aNIR system can eliminate these issues, as the NIR drying methodology can target the ink alone and not the substrate during drying. This allows ink to dry faster with lower applied heat temperatures creating higher productivity while lessening paper deformity.