Meet Ultraflex, the C.I. UV LED hybrid

KYMC, with more than 50 years of experience in Flexographic press design and in application integration teamed up with TSLC and Rainbow Pigment Co., Ltd to develop the next generation of CI Flexographic press. TSLC is the leading LED manufacturer and technology developer. TSLC has more than 10 years of experience in the LED industry providing reliable and quality UV-LED solutions to the global market. Rainbow Pigment is the ink expert with a strong R&D team to meet the demand of the market spanning across product lines and industries. Together, the work of art is born. We call it the Ultraflex.

In the constantly changing market, to take on the challenge and to remain competitive, printers need to adjust to the needs of the market. To be flexible, cost-effective and production efficient. The best quality comes at a high cost. The question is, will the customers pay for it? Low quality can be achieved through low cost. The question is, will the customer accept it? The printers that are able to find the balance between quality and cost are the ones that will remain competitive on the market.

There is no one right formula for production as there are various types of customers on the market. KYMC understands printers’ challenges by responding with the Ultraflex. The best part of Ultraflex is that you do not need to choose between a UV-LED press or a solvent/water-based press. You can have it all in one. Printers can take advantage of the UV-LED print stations on the Ultraflex when they can, and drawback to the solvent-based or water-based print stations when needed. In a nutshell, Ultraflex is a 2 in 1 investment designed to help printers get the most out of their investment.

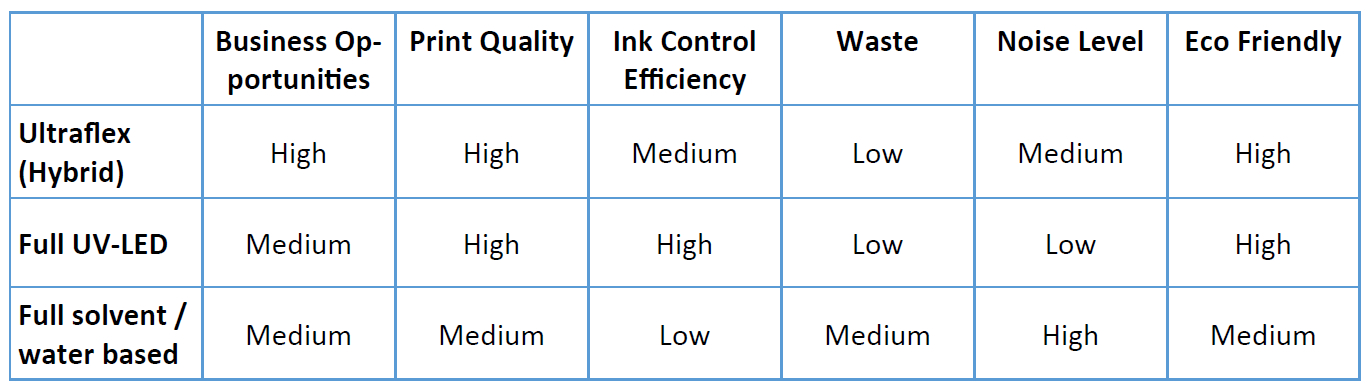

Table 1 : Ultraflex Comparison Chart

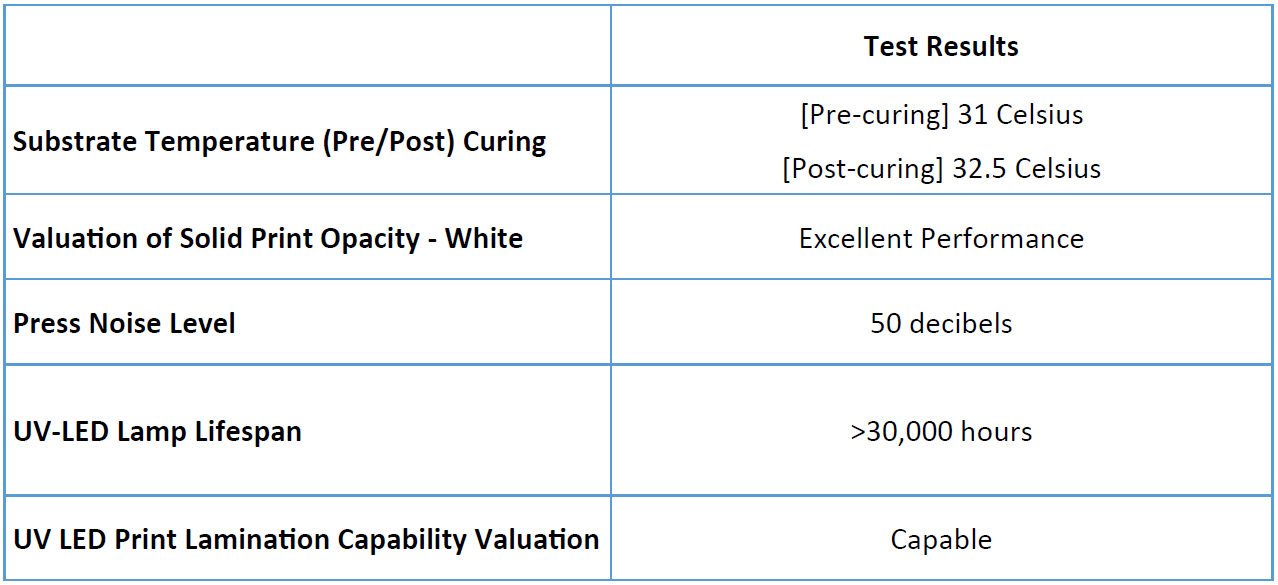

Table 2 : Ultraflex UV-LED Unit Test Results

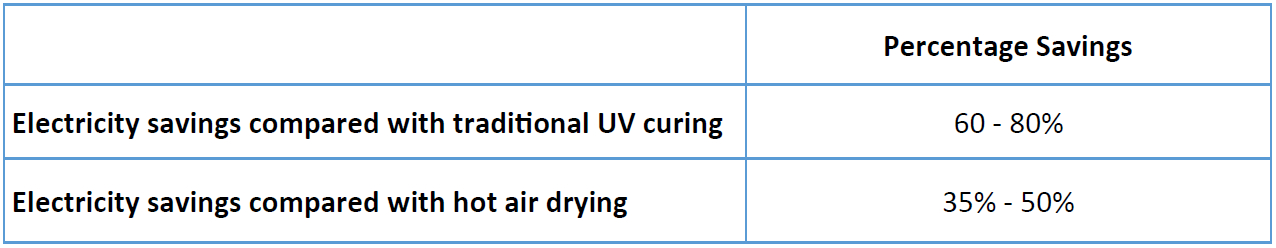

Table 3 : Electricity Savings Comparison Chart

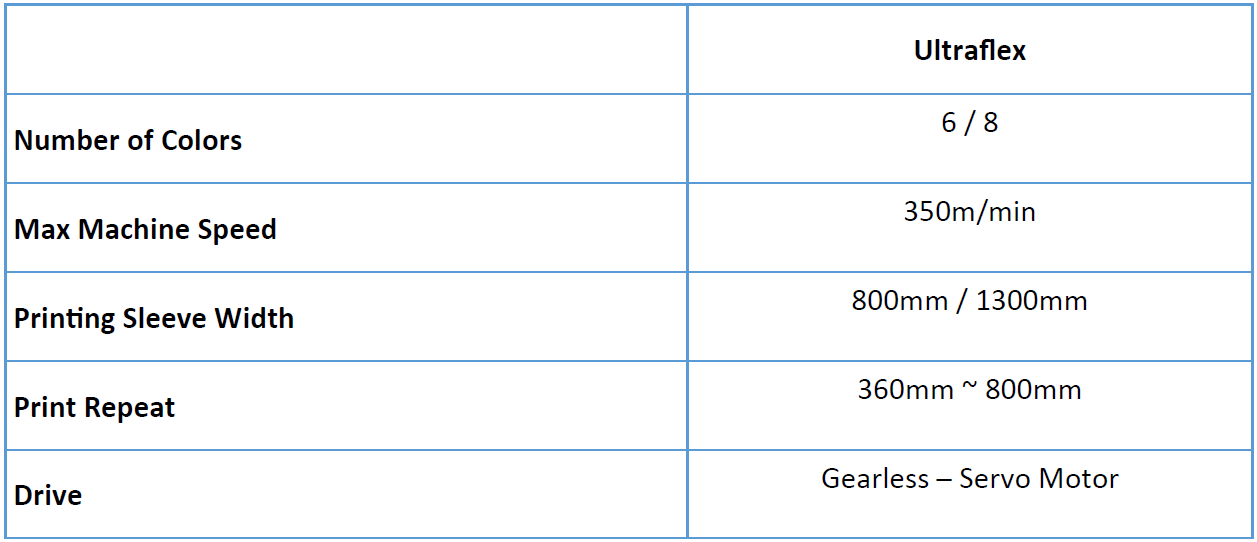

Table 4 : Ultraflex Press General Specification

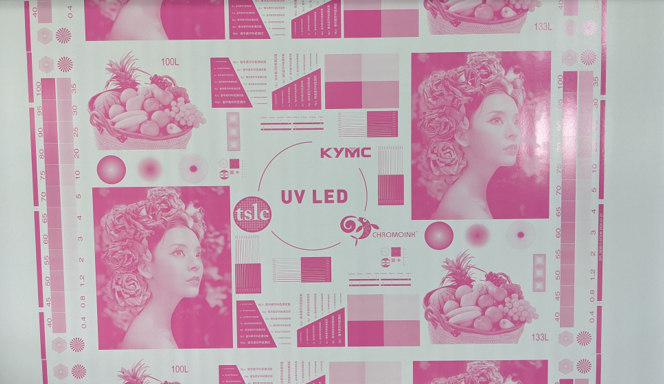

Figure 1 : Solid print with high opacity and providing a lifted relief touch

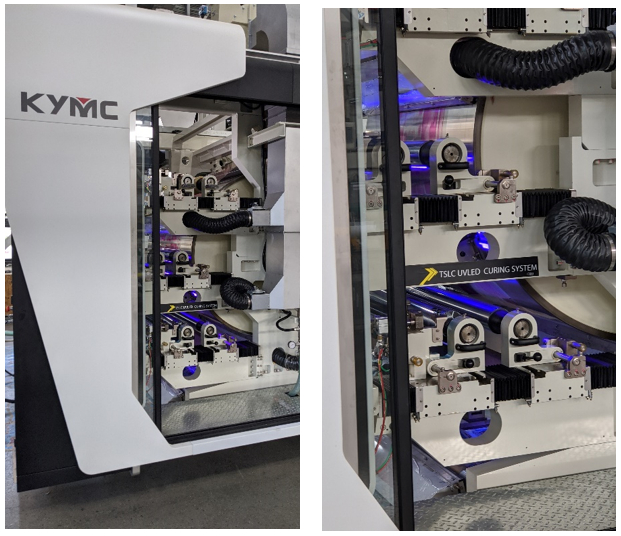

Figure 2 : The Ultraflex press

Figure 3. UV-LED Station