What’s the difference between SCADA and HMI?

Industry 4.0 is about the connection and commutation between machines and systems to ultimately reach decision making the absence of a human. More and more data are gathered throughout the production process. The machines get smarter with the increasing amount of data to work with. As a result, the production process to become more efficient and productive and less wasteful. The ideal situation is to form a network of these machines that are digitally connected with one another to create and share information that results in the full power of Industry 4.0

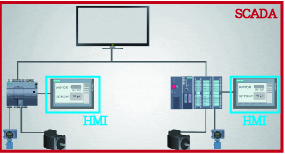

When it comes to data collection many people get confused about the difference between a SCADA and an HMI. SCADA stands for Supervisory control and data acquisition. SCADA is a combination of systems that are involved in monitoring and controlling the overall eco-system. SCADA receives data from sensors, RTU, PLC…etc. SCADA itself has its own HMI: Human Machine Interface. This is why a lot of people get confused and think that SCADA and HMI are the same. In short, HMI can be a part of the SCADA, but SCADA cannot be part of an HMI, as illustrated below.

Taking a vehicle as an analogy. The vehicle is like the SCADA, and inside your vehicle contains many sensors to bring information to your dashboard, which is essentially your HMI. HMI is essentially and user control station usually in the form of touchscreen or with buttons attached to it.