How to choose an Inline Flexo Press for Your Blown Film Extrusion Lines?

Your blown film extrusion line will likely run 24-7 without stopping. Therefore, when it comes to a different job where a new print design is required. How fast can you change the print setup? The anilox and plate sleeve design will allow you to quickly change your plate and anilox. A ready web path to switch from surface print over to reverse print and vice versa, or to print both surface and reverse on one path will allow a short-stop operation. A full servo-driven press for both registration and impression control prevents the need for a gear change during a job change. A recipe recall function will get your job set up with the right parameters in no time.

It’s nothing new that skilled press operators are hard to find on the market. Therefore, you should aim to depend less on operators to run your integrated processes smoothly. Having a user-friendly interface with a touchscreen HMI will allow easier monitoring and control for your operators. A fully digitalized registration and impression control will allow even a junior operator to set up the job quickly. A gearless press that does not require gear change will eliminate the need for gear-changing skills. The goal when selecting your inline flexo press is to depend on the machine as much as possible and depend on the experience and skills of the operator as little as possible.

Lastly, print quality is king. At the end of the day, without good print quality, quick job change and less dependency on the operator wouldn’t even matter. To deliver good print quality, your press should be built with a robust frame to minimize bounce. To have servo motors to guarantee excellent registration holding. To be able to fine-tune your kiss impression by one micron at a time. To equip with infeed and outfeed dancer to keep the printing tension perfectly. Not to mention having camera systems in place to allow operators’ quick responses. Having good control of ink viscosity will also be crucial for print quality. Therefore, a good ink management system will definitely help.

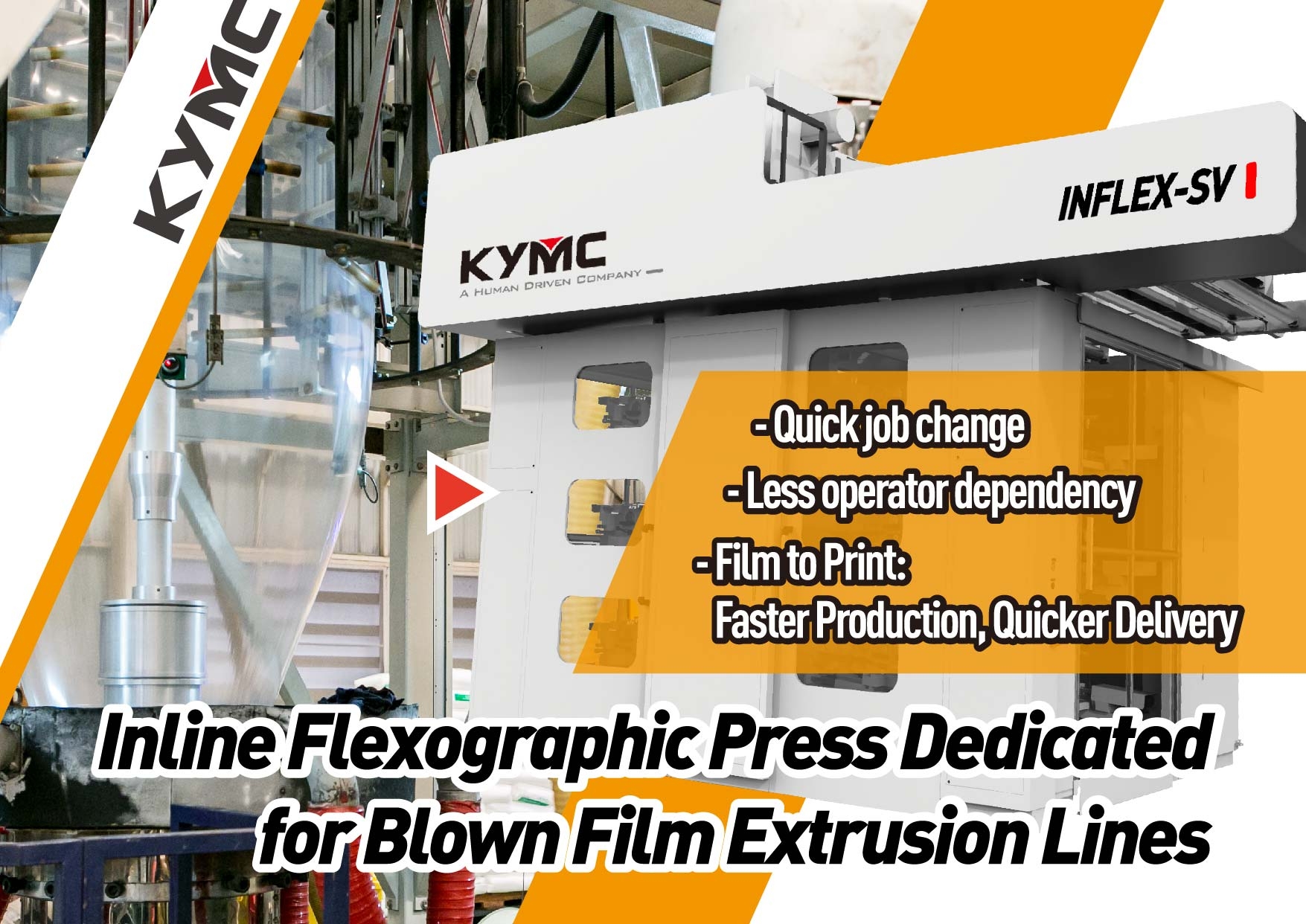

At KYMC we have the INFLEX-SV model which is an inline flexographic press dedicated to blown film extrusion line. This model is equipped with the technologies to achieve both inline surface & reverse printing. With its full servo motor design and sleeve-type configuration, it can accomplish quick job changes, minimizing material waste and operator requirements. Contact us to learn more about the INFLEX-SV how it can help you achieve your ESG goals and how it is an optimal solution for the blown film extrusion line.