テクニカル

| タイトル | 画像 |

|---|---|

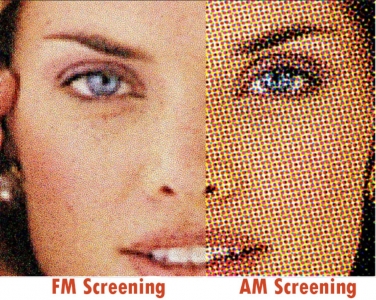

Must Know Screening Concepts to Succeed in Flexo Printing

AM screening and FM screening both has its advantages and disadvantages. In general FM screening are more suitable for details images, highlights, and shadows. AM screening performs better in mid-tones. FM are more consistent in its ink delivery, therefore, some say that it is able to produce a very stable appearance. This could be good things unless your print doesn’t match your proof. When the mismatch occurs, it will be difficult for press operators to tweak the appearance on the press. As Technologies advances, the newer XM screening takes advantage of AM & FM screening to produce to better print quality.