Technical

| 標題 | 圖片 |

|---|---|

September 24, 2023 | KYMC Marketing

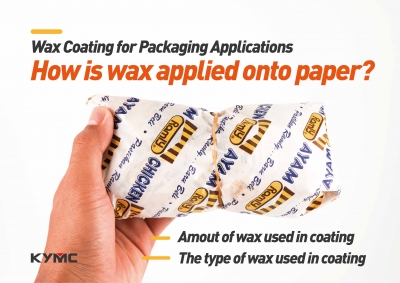

Wax coating is applied to paper to enhance the functionality during packaging. Wax will make the paper more durable and moisture resistance. Wax will keep the paper together when it comes into contact with moistures like grease or water. That’s how you are able to enjoy your greasy hamburger without getting grease onto your hand and unwrap your candy without it sticking to its packaging. Wax coating is all around us.

September 14, 2023 | KYMC Marketing

The route to a more eco friendly packaging is to switch from plastic materials over to paper materials. Is this really the case? Paper is a more recyclable material on its own. However, it is another story when paper is coated with plastic. If the recycling ecosystem for plastic coated paper is not set up in the neighborhood, plastic coated paper may be harder to recycle than plastic alone. Furthermore, the process of producing paper is more water intensive than plastics. Using paper also means taking the risk of over deforestation if paper is not sourced sustainably. So, is paper really more eco-friendly than plastic? In this article we will look at the bigger picture to explore the pros and cons for both paper packaging and plastic packaging.

July 26, 2023 | KYMC Marketing

If you are on a water-based printing operation or thinking about switching to a water-based printing operation, then you must understand the common water-based printing issues which include 1. Ink foaming 2. gelation 3. light ink color 4. and poor drying.

July 26, 2023 | KYMC Marketing

Flexible packaging is one of the most common packaging methods. The reason for flexible packaging’s popularity is due to its lightweight construction and its material savings when compared to rigid packaging. The construction of flexible packaging is the usage of laminating adhesive to bond different layers of film, foil, or paper together to form an effective structure to protect the goods within the packaging. The effectiveness of bonding and sealing of the different substrates will involve having the right adhesive mix ratio, the right coating weight, the right drying temperature and time, the right impression, and the right dyne level of the substrate. Some of the common coating and lamination adhesive issues include 1. low bonding strength 2. Tunneling in laminate 3. Bubbles in lamination 4. Ink bleed

June 30, 2023 | KYMC Marketing

There are many ways to make your printing more sustainable. Understanding what sustainable printing methods are available on the market can help you build up your business’s eco-friendly credentials. As environmentally friendly options are becoming more popular on the market, building up your eco-friendly credentials brings you closer to consumers.

May 30, 2023 | KYMC Marketing

You can start by understanding what substrate you would be printing on. Different substrates behave differently during printing. For instance, when applied with tension a film is more prone to stretch than paper. Print ink is easier to dry on paper than on film. Foil is more prone to tear than paper and film…etc. These different substrate characteristics will require different press designs. Not all presses work with all substrates. Even when you choose a substrate that you are going to print now. It is always a good idea to think in the mid and long term. To consider what other substrate you may target in the future and will your printing press be able to support you during the product line expansion. Some of the common substrates that you should consider are film, foil, tissue, non-woven materials, paper, and corrugated boards.

March 20, 2023 | KYMC Marketing

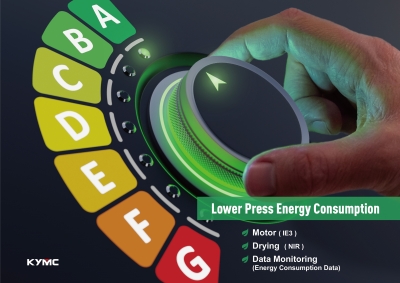

As sustainable development gains importance. Standards and goals are being set at a global level to reduce carbon emissions and ultimately reach net zero emissions. In the latest COP27 (Conference of the Parties), one of the world’s most significant summits on climate change, countries are coming together, reaching a consensus to combat climate change issues. As flexo printers, we can no longer stand on the sidelines. Actions must be taken starting with your own flexo press. There are many ways to increase efficiency and lower energy consumption on your flexo press. In this article, we will explore three different ways including 1. Selection of motor, 2. Drying method 3. Data monitoring.

March 15, 2023 | KYMC Marketing

Over time, consumers are becoming more conscious of environmental sustainability, the social impact and the transparency of a company’s governance. Therefore, flexo printers need to make the investments and to make the transformations necessary to keep up with this trend. There are many approaches to becoming an ESG orientated company. One approach is to establish a green water based flexo printing operation.

October 21, 2022 | Daywey Chen

Rotary dryers can come in two types of airflow configurations. The co-current system and the counter current system. Co-current system is designed so that the airflow and material flow in the same direction. On the other hand, counter current system is designed so that the airflow and the material flow in the opposite direction. To decide which system to adopt will depend on the type of substrate, ink and coating solution used. In this article we will lay out the advantages and disadvantages of both systems for you to review.

October 17, 2022 | Daywey Chen

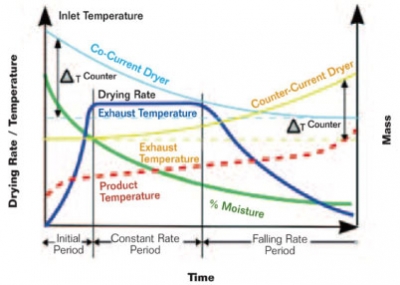

Flexographic printing, coating process, lamination process…etc. Whatever the process may be, drying plays a crucial role in the success and failure of the end result. The drying process should be seen as three phases instead of one. The initial phase, the constant rate phase, and the falling rate phase. At each phase the drying substrate will behave differently, affecting your end result. Understanding the role of each phase will help you achieve a balance between efficiency, throughput, and cost control during the journey to create the desired product.

September 20, 2022 | Daywey Chen

In general, as the press speed increases, the ink will dry faster on the anilox and plate. The reason is at higher speed, the air turbulence will increase, the shear force will increase, and more heat will be generated at the anilox and plate. To decrease the ink drying speed, the energy placed into ink drying will need to be reduced to compensate for the higher airflow and higher heat generation.

August 30, 2022 | Daywey Chen

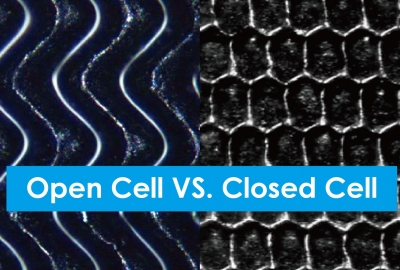

When choosing an anilox, should I go for an open cell or a closed cell system? The answer to the question depends on what you are working with (ink type, ink viscosity, plate LPI) and what you would like to achieve (printing, coating, half-tone, solid). In this article we will be looking into the characteristics of an open cell system and a closed cell system. To address issues such as ink spitting and pinholes and how to solve them from a cell system’s perspective. Furthermore, going into a few scenarios including high speed printing, UV ink application, special ink / coating enhancement, where certain cell designs may be recommended over the others.