Technical

| 標題 | 圖片 |

|---|---|

April 7, 2020 | Daywey Chen

One of the main purposes of packaging is to communicate with the customer about the product. However, that’s not all, packaging serves great importance when it comes to functionality. By functionality, we mean the ability to keep the product away from external contamination, damages, humidity, temperature and light. To keep the product inside of the packaging from leaking out, for instance to keep the odor, liquid inside of the packaging. Often times, multiple layers of materials are laminated together to achieve the functionality required, as different packaging materials have different properties. Today we are going look into a few common packaging materials used on the market and their properties.

February 25, 2020 | Daywey Chen

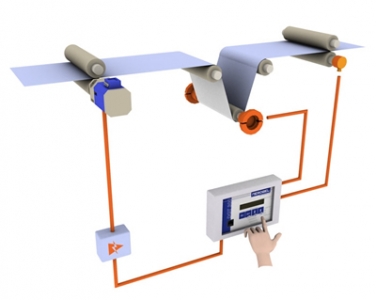

How important is it to have control over your ink viscosity? Ink viscosity affects how well your ink is able to transfer over from the anilox to the plate, and from the plate onto the printing substrate. It affects how well your ink will dry on the substrate. In general, your press production speed, and the quality of your print is highly correlated to the ink viscosity. In Flexographic, having a suitable ink viscosity makes all the difference.

Having control over your ink viscosity can easily get you USD77,568 of savings per year...see our calculation

December 11, 2019 | Zack Chen

印刷環境的溫溼度對於印刷品質有著很大的影響,當環境溫度越高時,油墨中的溶劑揮發速度則越快,這會造成油墨黏度的提高,油墨流動性不佳,大大降低油墨轉移的性能...

June 6, 2019 | Alex Liao | Daywey Chen

The number of functions equipped into the ink supply and washing system can vary. The more function the more cost. At the end of the day, we are not trying to find the best inking system with the most function. Our goal is to find the most suitable system for your needs. Below are 5 things that you can look into to help you select your ink supply and washing system.

April 16, 2019 | Daywey Chen

According to TAPPI testing guide (Technical Association of the pulp and paper industry) when controlling the web tension, a general guideline is to apply 5% ~ 25% of the maximum web strength, and around 0.5 ~ 1 PLI/mil of thickness.

March 25, 2019 | Daywey Chen

Industry 4.0 is about the connection and commutation between machines and systems to ultimately reach decision making the absence of a human. More and more data are gathered throughout the production process. The machines get smarter with the increasing amount of data to work with. As a result, the production process to become more efficient and productive and less wasteful. The ideal situation is to form a network of these machines that are digitally connected with one another to create and share information that results in the full power of Industry 4.0

March 22, 2019 | Daywey Chen

When choosing a Servo motor there are a few specifications to select from. An AC current type or a DC current type servo motor. Is the motor brushed or brushless, and is the motor synchronous our asynchronous.

January 18, 2019 | Daywey Chen

Nozzles, picoliter, thermal printhead, piezo-electric printhead, drop-on-demand(DoD), continuous inkjet, binary, greyscale are specification describing the digital printhead. Understanding the meaning of these terms will help you understand how the printer operates and will help you to select the right digital printhead for the right job. However, it is rare that for the supplier to stop and explain them. So here is where we stop and explain it to you.

November 2, 2018 | BST Eltromat

BST eltromat International offers various solutions for 100% inspection and web monitoring for quality assurance in narrow, mid and wide web applications such as label and package printing. The inspection systems from the BST eltromat cooperation partner Nyquist Systems complement this offer.

November 23, 2018 | Daywey Chen

In today’s competitive environment, printers need to be as competitive as possible. To be competitive, one needs to choose the right tool for the right job. Wide web press and narrow web press both has its advantages and disadvantages. At the end of the day, it comes down to what your main goal is. For instance, is your main goal to be as environmentally friendly as possible to save cost from pollution emission and to build up a good eco- friendly company image? Is your main goal speed since most of your job orders are very long runs? Is your main goal for printing labels at small quantity?

October 19, 2018 | Christine Duggan

This week KYMC invited Flexo Concepts to share about press room improvement from a doctor blade standpoint. Every industry has its challenges, and for the flexo printing industry, they include anilox scoring and pressroom injuries related to the use of steel doctor blades. Fortunately, due to advancements in polymer materials and tip designs, press operators no longer have to trade the safety benefits of plastic doctor blades for the effectiveness of steel...

September 28, 2018 | Daywey Chen

Typically speaking water-based ink could be considered if your application is to run at slower printing speed and on an absorbent substrate. The water-based ink that consists of much less organic solvent could provide printers with less VOC emission issues to worry about. At KYMC we had a customer that ran solely on water-based ink as VOC emission permits are required in the region. As the sales orders fluctuate from month to month, the VOC emission permit may be insufficient or excessive depending on the order quantity of that month. To avoid this issue...

-01.jpg)