What is a Servo motor and how does it benefit your printing operation?

AC / DC – the type of current is used

This indicates the inherent ability to control the speed

DC- The speed is directly proportional to the supplied voltage with a constant load

AC- The speed is determined by the frequency of the applied voltage and the number of magnetic poles

AC can withstand higher current, more used more often in jobs where high repetition and high precision is required

Brushed / Brushless

The DC motor can be generally categorized into brushed or brushless. DC can be commutated mechanically with brushes, or electronically without brushes

Brush motors are generally less expensive and simpler to operate. Brushless are generally more reliable, more efficient and less noisy

DC motors generally provide a very accurate and fast response to start or stop command signals

AC Motors are generally brushless

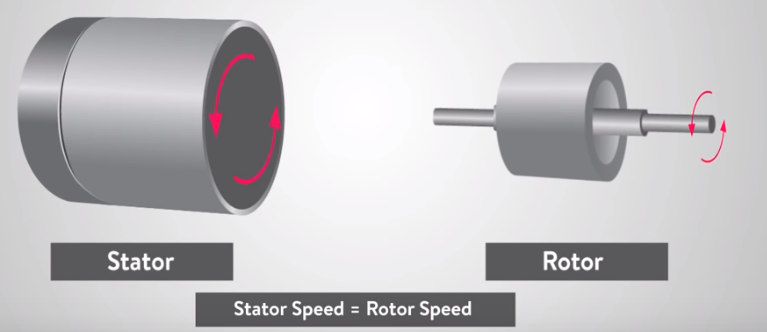

Synchronous / Asynchronous

AC are generally categorized as synchronous or asynchronous. If synchronous the rotor rotates at the same speed as the stator. In an asynchronous type also known as the induction motor, the rotor rotates at a slower speed than the stator rotatory magnetic field.

AC motor generally can withstand higher voltage to accomplish greater torque

The advantage of the servo motor is that it has high efficiency and with great precision. One of the most important servo motor’s attribute is its control loop design that takes in constant feedback to monitor the current velocity, torque, and position. Therefore, is able to make the necessary adjustment when movement is in error. Servo motors run more smoothly than a stepper motor, Typically a servo motor will provide 2-3 times the speed of a stepper motor. As the speed(rpm) of the servo motor increase, its torque remains constant, unlike the stepper motor the torque decreases as the speed increase. Servo motors are also quieter than stepper motors

The disadvantage is that it is more expensive. Moreover, Servo motors is more complex as it requires tuning, by which user optimize the internal algorithm to control the torque, velocity, and positioning of the motor

The servo drive installed on the printing press will allow your printing operation to have a tighter registration, higher automation and have a faster response to error correction. In short, saving you time and lowering your waste to help you achieve higher profitability.

Article by Daywey Chen, KYMC